Introduction

Salt, an essential mineral used globally, not only enhances flavor in our cuisine but also serves numerous industrial purposes. The packaging of salt has undergone a significant transformation over the years, evolving from basic bulk containers to sophisticated custom bags tailored to meet specific market needs and consumer preferences. This article explores the journey of salt packaging from its humble beginnings to the innovative solutions we see today.

The Early Days: Bulk Packaging

Historically, salt was transported and sold in large, unwieldy bulk containers. These methods, while practical for industrial use or large-scale culinary operations, offered little in terms of convenience or branding opportunities. Bulk packaging was primarily functional, focusing on the simple objective of moving salt from producer to user without much consideration for preservation, usability, or marketing.

Shift Towards Bagged Salt

As market demands and consumer lifestyles began to change, the salt industry recognized the need for more practical and user-friendly packaging options. The introduction of bagged salt marked a significant shift, making salt more accessible to the average consumer. These bags, although initially quite basic, allowed for easier transport, storage, and use of salt in households and businesses alike.

The Rise of Custom Salt Bags

The real game-changer in the industry has been the advent of custom salt bags. These bags are specifically designed to address a wide array of needs, including:

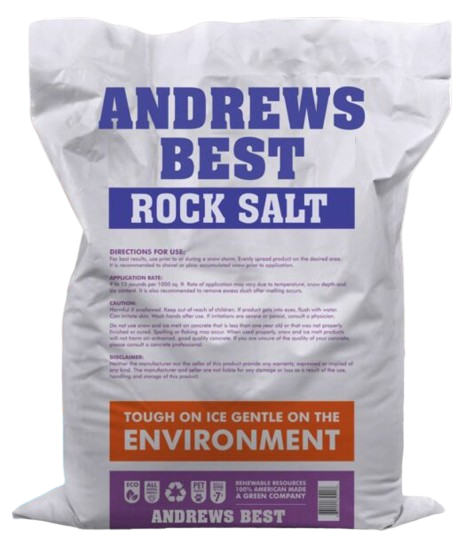

- Branding and Design: Custom bags offer the opportunity for companies to brand their salt products, differentiating themselves in a competitive market. Through eye-catching designs and logos, brands can create a unique identity that appeals to consumers.

- Improved Functionality: Customization has led to innovations in bag functionality, including resealable zippers, easy-tear openings, and moisture-resistant materials. These features enhance the consumer’s experience by ensuring the salt remains dry, is easy to access, and can be stored conveniently.

- Specialized Applications: Custom bags cater to various market segments, such as food-grade salt for culinary use, pharmaceutical-grade for medical applications, and industrial-grade for de-icing or water treatment. Each application may require different bag sizes, materials, and protective features.

- Sustainability: With growing environmental concerns, custom salt bags have also evolved to include eco-friendly options. Biodegradable and recyclable materials are increasingly used, reflecting a commitment to sustainability within the industry.

Technological Advancements

Technology has played a pivotal role in the evolution of salt packaging. Advanced printing techniques allow for vibrant, high-definition designs on salt bags, making them more attractive on store shelves. Moreover, the integration of smart packaging technologies, such as QR codes, enables consumers to access detailed product information with a simple scan.

Conclusion

The evolution of salt packaging from bulk containers to custom bags reflects the industry’s responsiveness to changing consumer needs and environmental concerns. Today, custom salt bags not only serve practical purposes but also offer significant branding, sustainability, and convenience benefits. As consumer preferences continue to evolve, we can expect further innovations in salt packaging, reinforcing the industry’s commitment to quality, functionality, and environmental stewardship.

The journey of salt packaging is a testament to the dynamic nature of product packaging and its impact on marketability, consumer satisfaction, and sustainability. As we look to the future, the possibilities for further innovation in salt bag design and functionality are endless, promising exciting developments for consumers and the industry alike.